The way to distinguish between nylon Oxford cloth and polyester Oxford cloth is to scrape it with your fingernails. After scraping, the obvious traces are polyester Oxford cloth, and the traces are not obvious, nylon Oxford cloth. However, this method is not as intuitive as the following method. Easy to argue.

Nylon Oxford When the cloth is burned with fire, the color of the smoke becomes white. The burned residue becomes plastic. When approaching the flame, it quickly shrinks and melts into a white gel. It melts, drips and bubbles in the flame. There is no flame when burning. When leaving the flame It is difficult to continue burning, and the light brown melt is not easy to grind after cooling. Nylon Oxford cloth has good elasticity and wear resistance, the dyeing temperature is 100 degrees, and it is suitable for dyeing with neutral or acid dyes. The high temperature resistance is worse than polyester, but the strength is better and the pilling resistance is better.

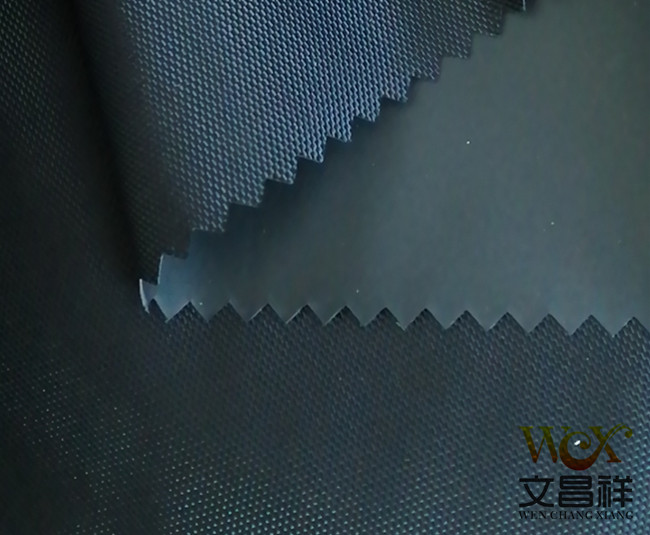

When polyester Oxford cloth burns, black smoke and black ash will float up. After burning, the ashes will turn into dark brown hard lumps that can be crushed with your fingers. The dyeing temperature is 130 degrees, and the hot melt method is generally baked below 200 degrees. The main characteristics of polyester Oxford cloth are better stability. Generally, adding a small amount of polyester to clothes can help with wrinkle resistance and plasticity. The disadvantage is that it is prone to static electricity and pilling.

Nylon Oxford cloth The performance is better than polyester oxford cloth, but the cost is also higher than polyester oxford cloth. Nylon Oxford cloth has better wear resistance, stress resistance, color fastness, gloss and other aspects than polyester Oxford cloth, and is less prone to wrinkles.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p