Aramid-based conductive fiber: the perfect combination of flame retardant and antistatic

Aramid-based conductive fiber: the perfect combination of flame retardant and antistatic

Conductive fiber is a new type of fiber that appeared in the 1960s. It usually refers to fibers with a specific resistance (or resistivity) below 107Ω·cm under standard conditions (20°C, 65% relative humidity). Generally, conductive fibers can be roughly divided into two categories: inorganic and organic. Among them, inorganic includes various metal fibers, and organic includes nylon, polyester, acrylic, polypropylene, polyester-nylon composite, etc.

Simplified chemical reaction formula for producing aramid

With the development of society and the continuous advancement of modern science and technology, there is an increasing demand for antistatic fabrics in the military and civilian fields, and the performance standards of conductive fibers are also constantly improving. Currently, the commonly used flame-retardant fabrics on the market are mainly finished cotton flame-retardant fabrics and intrinsically flame-retardant aramid fabrics. In order to meet the anti-static needs of the public, about 2% polyester or nylon-based conductive fibers are generally added to these fabrics.

Nylon-based and polyester-based conductive fibers themselves are not flame retardant. The addition of such conductive fibers to flame-retardant fabrics often affects their original combustion-supporting properties. In order to solve this problem, Yantai Taihe New Materials Co., Ltd. has developed a new type of conductive fiber based on meta-aramid.

This fiber is the world’s first aramid-based conductive fiber, with excellent conductive properties and a specific resistance of up to 104Ω·cm at room temperature. At the same time, it retains the original excellent flame retardant properties of aramid. Its limiting oxygen index can reach more than 28%. It is an intrinsic flame retardant fiber and will not burn, melt or produce droplets in the air.

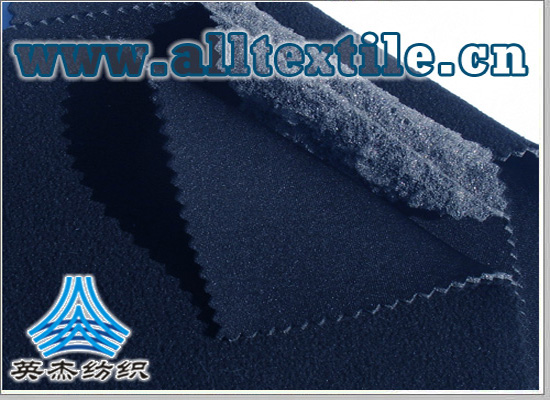

Compared with other base conductive fibers, aramid-based conductive fibers can effectively enhance the flame retardancy of fabrics. When 2% nylon-based or polyester-based conductive fibers are added to aramid fabrics, the limiting oxygen index is 30%. When 2% aramid-based conductive fibers are also added, the limiting oxygen index of the fabrics can reach 39%-40%.

Due to the difference in the high temperature resistance of the base material itself, aramid-based conductive fibers also show excellent high temperature resistance than conductive fibers of other base materials. Similarly, when placed at 265°C for 5 minutes, the state of the aramid-based conductive fibers did not change significantly, while the polyester-based conductive fibers shrank significantly, and some even began to melt.

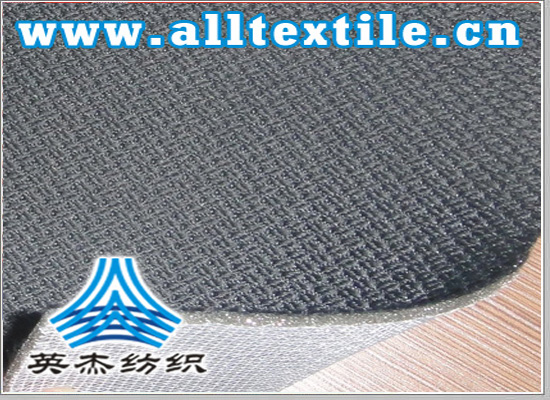

At the same time, aramid-based conductive fiber also has the characteristics of low rigidity and high elongation, can be processed into any length, and has a soft hand feel. After being blended with other fibers, it can meet the various index requirements of antistatic fabrics while improving Flame retardant properties of fabrics.

As the country pays more and more attention to personal protection, various industries have increasingly higher requirements for special protection such as flame retardancy and antistatic. With its excellent performance, aramid-based conductive fiber has been successfully used in fire-fighting suits, emergency rescue suits, petroleum work clothes, fire protection and so on. It can be applied in special protective fields such as blankets and touch screen gloves. At present, the high-tech textile market is growing rapidly. The protective clothing industry is growing at an average rate of 6%-10% per year. Some special demand areas are even growing at a rate of 30% per year. Aramid-based conductive fibers will be used in more and more applications. fields are widely used.

The National Oilfield Petroleum Equipment Testing and Inspection Center for Safety Production is the only national safety production testing and inspection Grade A qualification institution authorized by the State Administration of Work Safety of Sinopec Group Corporation. It also has a Metrology Certification Certificate (CMA) and a Laboratory Accreditation Certificate (CNAS). There are more than 150 sets (sets) of professional labor protection equipment testing equipment. Currently, it is able to carry out inspections of more than 30 products in five categories: head protection, hand and foot protection, trunk protection, fall protection and respiratory protection. .