Research on the application of carbon fiber composite materials in high-speed EMUs

High-speed EMUCarbon Fiber Composite MaterialsApplication Research

Abstract: Through the analysis of the development status and technical characteristics of high-speed trains, combined with the performance advantages of fiber composite materials and the investigation of the current industry situation, the necessity of the development of diversified structures and materials is revealed, and it is pointed out that fiber composite materials are an effective way to achieve the balanced development of various train performances. . The application of composite materials for high-speed EMUs at home and abroad was introduced in detail, and the application examples of fiber composite components under the integrated design concept of CRRC Sifang were demonstrated. The development direction of composite materials for high-speed EMUs was prospected, and it was proposed to accelerate the application of domestic carbon fiber composite materials in rail transit. Feasible suggestions for application in China, in order to improve international competitiveness and enhance the industry’s voice.

Introduction

The increasingly frequent world economic and trade exchanges and the gradual improvement of urbanization level have promoted the rapid development of the high-speed railway industry, and the world’s high-speed railway has reached an unprecedented scale. my country’s high-speed train operating mileage and train ownership account for more than 50% of the world’s share. Currently, there are 54 lines in operation across the country, with a total mileage of more than 20,500 kilometers, and 2,122 EMUs operating online (1,313 EMUs at 350 kilometers per hour, 809 EMUs at 250 kilometers per hour). It is expected that in 2020, 30,000 kilometers will be built, and the total number of trains More than 3,500 groups. With the successive launch of high-speed train projects in Indonesia, Thailand, Russia and other countries, the high-speed train market has entered a new round of rapid development. The huge market demand provides a good opportunity for the advancement of rail transit technology and the promotion and application of new technologies and new materials. . China’s rapidly developing high-speed train industry should seize the opportunity, implement the go-out strategy, seize the technological commanding heights of new technologies and new materials, and continuously enhance the industry’s voice.

With the continuous improvement of the world’s high-speed train pedigree, users’ demand for personalized customization has gradually matured and shown a diversified development trend. While users are pursuing train speed, they are beginning to pay more attention to how to improve service quality, how to improve train energy conservation, environmental protection, comfort, and convenience. At present, while the speed of traditional trains made of metal materials continues to increase, it becomes more difficult to solve the problems of vibration, impact, resistance, and noise. And when dealing with complex and changeable service environments such as plateaus, deserts, high temperatures, high cold and high altitudes, existing materials are becoming increasingly inadequate. Aluminum alloy car bodies have problems such as stress corrosion, difficult surface treatment, high welding requirements, and low fatigue strength; stainless steel car bodies have problems such as sealing, local buckling, and welding deformation; carbon steel car bodies are prone to corrosion and are not conducive to lightweighting. Problems such as large welding deformation. The technical solutions for traditional structures and materials to meet the challenges are not rich enough and technically difficult, and cannot meet users’ requirements for comprehensive train performance. How to achieve further lightweighting of trains, reduce axle load, stabilize adverse factors of speed, solve the contradiction between lightweighting and various performances (strength, vibration, noise, heat insulation, radiation), and find a balance between train technical performance to better adapt to the situation. Development trends are also the key to occupying the future international market.

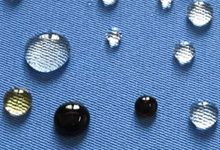

When traditional single-component structural materials are difficult to meet performance requirements, diversification of structures and materials is imperative. Advanced materials such as aramid fiber composite materials (AFRP), glass fiber composite materials (GFRP), carbon fiber composite materials (CFRP), honeycomb sandwich structures, foam sandwich structures, and functional laminates with excellent properties such as lightweight, high strength, and high weather resistance The mature engineering application of composite structures such as aircrafts and ships in the field of transportation equipment such as aircrafts and ships provides feasible guidance for solving the problem of lightweighting of high-speed trains. The mature application of fiber composite materials in the field of high-speed trains will improve the comprehensive performance indicators of rail vehicles and is expected to systematically solve common problems such as lightweight and environmental adaptability in the field of metal material applications. Countries around the world have conducted a lot of research on how to quickly promote the mature application of fiber composite materials in the field of rail transit.

Fiber composite material performance and industry status analysis

Comparative analysis of the performance of fiber composite materials and metal materials. It can be seen from Table 1 that fiber composite materials have a smaller density than metal materials, have obvious advantages in lightweight, excellent mechanical properties, high tensile strength and specific strength, and can fully meet the material performance requirements of trains. During the development process of high-speed train applications, after comprehensive analysis of technical requirements, material performance, process, cost and other factors, carbon fiber composite materials are preferred for the main load-bearing structure, glass fiber composite materials and other materials can be used for secondary structures, and aromatic materials can be considered for local impact-resistant parts. Polyester fiber composite material.

The development and large-scale adoption of carbon fiber composite components must first ensure the stable performance and production capacity of the raw materials. Table 2 is an analysis of the current industrial status of carbon fiber and other composite materials at home and abroad. Generally speaking, foreign raw materials and related product technologies are mature and��;

3) Encourage domestic manufacturers and research institutions to think strategically about the application of CFRP composite materials in high-speed rail and actively participate in the construction of the industrial chain.

China is currently in a prosperous period of rail transit construction and has become the world’s largest urban rail transit market. This is a brand-new and promising application field. We should seize this opportunity to establish an integrated research platform among industry, academia, research and application, conduct in-depth research on composite material manufacturing technology and batch products with independent intellectual property rights, and further promote The large-scale application of CFRP in the field of rail vehicles, especially its application in large, complex, and general-purpose load-bearing structural parts, promotes the development of my country’s high-speed rail transit industry.