Processing and Application of Aramid

Processing and Application of Aramid

In the 1960s, DuPont scientist Stephaine Kwolek studied aromatic polyamides and successively developed high-strength and high-modulus para-aramid Kevlar and meta-aramid Nomex with good flame retardant properties. An industrialized product, for which she won the National Medal of Science and Technology in 1996, which represents the highest honor for scientific and technological innovation in the United States. After the advent of aramid, it has attracted widespread attention for its excellent performance, and scientific researchers from various countries have also invested considerable efforts in research. At present, many countries such as the United States, Russia, Japan, South Korea and China can industrialize production and use it in national defense industry, aerospace, electromechanical, construction, automobiles, sporting goods, etc.

my country has been researching the development of aramid since the 1970s. After years of development, it first achieved a breakthrough at Yantai Spandex Company in 2004, realizing the industrial production of meta-aramid 1313. In June 2011, the company announced para-aramid The 1414 thousand-ton production line was successfully put into operation. In recent years, many domestic companies have launched thousand-ton production lines including aramid 1313, aramid 1414, aramid III, etc. With the localization of various aramid products, the price monopoly of large foreign companies has been gradually broken. With the development of my country’s national economy and the improvement of people’s safety awareness, if the cost factors that restrict the application of aramid downstream products can be broken through, aramid products will be used more and more in our country.

1. Liquid crystalline basis of aramid processing

Due to the structural characteristics of aromatic polyamide, aramid fiber has high thermal stability, which also makes aramid fiber unable to be processed by conventional heating and melting methods. However, the amide structure of aramid fiber makes it soluble in strong protonic acids such as concentrated sulfuric acid, chlorosulfonic acid, etc., or aprotic amide solvents. However, when using amide solvents, calcium chloride or lithium chloride is required as a solvent. Co-solvent to improve the solubility of aramid. Taking advantage of this characteristic, aramid can be dissolved in sulfuric acid or amide compounds for processing. The unique rigid structure of aromatic polyamide allows the aramid solution to exhibit anisotropy, that is, a liquid crystal phase, under certain conditions. The performance of aramid products processed under such liquid crystal phase conditions can be greatly improved. To produce an anisotropic liquid crystal solution, the molecular weight of the aramid product must reach a certain value, the concentration of the solution must reach a critical value, and the temperature must be within a certain range.

In the 1960s, Stephanie Louise Kwolek studied the effects of polybenzamide (aramid 14, PBA) and polyphenylene terephthalamide (aramid 1414, PPTA) on sulfuric acid through optical, mechanical and other methods. Liquid crystal phase behavior in: When the concentration of sulfuric acid exceeds 98%, the concentrated solution of aramid (greater than 8%) will exhibit anisotropy, that is, a liquid crystal state. Guan Baoqiong also used a similar method to study the phase behavior of sulfuric acid solutions of poly-p-phenylene terephthalamide at different concentrations and temperatures. He found that the PPTA/sulfuric acid solution not only changed from an isotropic solution to an isotropic solution as the concentration increased, The anisotropic solution is then further transformed into an anisotropic solid; and the system at a certain concentration has a temperature range. Within this temperature range, it is an anisotropic liquid. Below this temperature range, it is an anisotropic solid. High Within this range, it becomes an isotropic solution.

Stephanie Louise Kwolek also used a similar method to study the phase behavior of aramid products in an amide solvent + co-solvent system. Taking the PBA/DMAc and LiCl system as an example, when a certain amount of LiCl is added as a co-solvent, as the solution concentration increases, the solution first changes from an isotropic solution to a solution that is both isotropic and anisotropic. solution, then transform into an anisotropic solution, and finally into an anisotropic solid. When the temperature of a certain concentration of PBA/DMAc and LiCl system solution changes, its phase change trend is similar to that in concentrated sulfuric acid solution.

Scientific researchers found that in the same type of aramid solution system, the viscosity of the anisotropic solution is lower, so when its viscosity changes with concentration and temperature, there will be a trough in the anisotropic phase. This is extremely beneficial to the processing of aramid fiber. When the aramid solution is in the anisotropic phase, that is, the liquid crystal state, the molecular segments will be oriented under the action of stress such as shearing. These have important implications for the mechanics of aramid performance products. Fully studying the liquid crystalline behavior of aramid in solution can enable us to have a more complete understanding of the performance of aramid products.

2. Classification of aramid processing

Aramid has excellent properties such as high strength, high modulus and high temperature resistance. Its strength is 5-6 times that of steel wire, its modulus is 2-3 times that of steel wire or glass fiber, and its toughness is 2 times that of steel wire. While aramid has high performance, it also causes processing difficulties. Because aramid cannot be melted, several aramid products that have been industrialized cannot be injection molded, extruded, etc., and can only be processed in solution. However, processing in solution state can only adopt processes such as spinning and film forming. The common processing method of aramid is to spin into filaments, or to obtain short fibers through pulping and chopping of filaments. Fiber products such as filament and pulp have relatively narrow application fields. In order to obtain wider applications and better utilize the excellent properties of aramid, they must be further processed. For example, although filaments can be used as bone materials in composite materials, they areFurther processing. The secondary processing products of aramid are aramid cloth and aramid paper, which are similar to our commonly used cloth and paper, which is conducive to further processing of practical products.

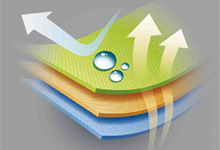

Since aramid cloth is cloth, it can be processed like cloth, such as clothing or other cloth products. Aramid cloth can also be used as a skeleton in composite materials. Aramid has high heat resistance, and when meta-aramid encounters a sudden strong temperature of 900-1500°C, the cloth surface will quickly carbonize and thicken, forming a unique thermal insulation barrier with outstanding fire protection effect. Therefore, clothing made of aramid fiber was first used as firefighting clothing. At present, firefighting suits of various colors and styles woven using domestically produced aramid fibers have begun to be equipped with our country’s forest police and firefighting forces.

Further processing of aramid paper can produce paper honeycombs. Aramid itself has excellent properties. The honeycomb structure is lightweight while maintaining the mechanical and thermal properties of aramid. It also has high sound absorption efficiency, which can greatly reduce noise pollution. Therefore, aramid paper honeycomb is widely used as a sandwich structure in aerospace, railways and other high-end decorations. Our country is currently vigorously developing large passenger aircraft and large military transport aircraft. Today’s aircraft materials have entered an era of high-modulus, lightweight composite materials. The advancement of aircraft is largely reflected in the use of composite materials. The high requirements for safety, economy, comfort and environmental protection of large aircraft projects determine the high demand for composite materials. As a high-performance lightweight aviation material that has been maturely used in foreign aircraft, aramid paper honeycomb structure will inevitably receive attention. With the six major railway speed increases, China’s railways have entered the era of electrified high-speed trains. EMUs have become the main models of rapid railway passenger transport, and high-speed trains are also being launched continuously. High-speed trains have high requirements for lightweight vehicles. New lightweight structural materials such as aramid honeycomb will be more widely used in high-speed trains due to their excellent comprehensive properties.

In addition, aramid paper can also be bonded with films such as polyester to obtain flexible insulation materials, which have the flexibility and excellent dielectric properties of polyester films while maintaining the insulation, heat resistance, thermal conductivity, and Tear strength, can be used as heat-resistant F, H class insulation materials.

3. Application of aramid

Aramid fiber has excellent properties, making it needed in almost every industry of the national economy, and its applications are also more extensive. In order to better summarize and subdivide the application of aramid fiber, the application of aramid fiber is analyzed using the previously established aramid processing classification theory. The situation is shown in Table 1.

Processing and Application of Aramid

Processing and Grading

Processing form

Product function type

Application areas

First level processing

Filament

Reinforcing materials

Optical fiber reinforced core and armor, indoor optical cable and ADSS power overhead optical cable

Tires, conveyor belts, hoses, cables and other rubber products

Among other composite materials

Fiber meal

Reinforcing materials

Replace glass fiber for injection molding, etc.

Friction materials

Replace asbestos for clutch linings, brake pads, etc.

Secondary processing

Aramid cloth

Reinforcing materials

Body armor, bulletproof armor, etc.

Used for the reinforcement and repair of civil structures such as bridges and buildings

High temperature filter materials

Widely used in the filtration of high-temperature flues and hot air in chemical, cement, smelting and other industries

Aramid paper

Insulating materials

Used as insulation materials for coil windings, phases, turns, and line terminals in transformers and motors. Printed circuit boards, etc.

Flame retardant materials

Heat insulation and flame retardant materials for background curtains, wallpapers, and spotlights in public facilities such as theaters and hotels. Used in aerospace, railway and other thermal insulation and flame retardant materials. Engine insulation materials, spark plugs, high temperature resistant hoses and other thermal protection materials, radiation hose flame retardant materials.

Wave-transparent materials

Broadband wave-transparent materials for aircraft, missiles, and satellites are used in radar radomes and wave-transparent windows for Identifier Friend or Foe.

Filter materials

It is widely used in high-temperature flues, hot air filtration and other special environments such as high temperature and corrosion in chemical, cement, smelting and other industries.

Other aramid fabrics

Reinforcing materials

Aramid gloves, etc

Dip cord is used for tires and rubber hoses

Aramid cable

Sealing materials

Aramid packing

Tertiary processing

Clothing, etc

Thermal insulation and flame retardant materials

Firefighting clothing, fire blanket

Paper Honeycomb

Structural materials

Structural materials such as wings, cabin doors, fairings, etc.

Sandwich materials for high-speed trains, yachts, racing boats and other high-performance requirements

High-end decoration materials such as lining boards, floors, and partition walls

Wave-transparent materials

Broadband wave-transparent materials for aircraft, missiles and satellites

4. Outlook

Since the reform and opening up, China’s economy has made great progress, and people’s needs for science and technology and culture have also become higher and higher. Especially as the safety awareness of Chinese people increases, the excellent properties of aramid will be used more in occasions with high performance requirements or safety protection. Aramid has attracted much attention due to its excellent properties, and its processing method makes its application range wider. I believe that with the development of new technologies, the emergence of new processing equipment and new processing techniques, aramid fiber, which used to be used in high-end industries such as military industry and aerospace, will definitely “fly into the eyes of ordinary people” “Home” has entered more deeply into our daily lives and become a common product, better protecting the safety of our lives and property and better serving the people.

Safe and better serve the people.